This is a new clause that provides terms and definitions specific to this standard. It replaces subclause 1.9 and Annex S from the previous edition. This is a new clause listing normative references. This is 24th Edition and underwent the following changes: The American Welding Society revised AWS D1.1:2015 and published AWS D1.1:2020 based on a five-year revision cycle. Strengthening and Repair of Existing StructuresĬhanges/Modifications to AWS D1.1-2020 Clauses UT of Tubular T-, Y-, and K-Connectionsġ1.Supplementary RT Requirements for Tubular Connections.PJP Groove Welds for Tubular Connections.Production Welding Positions, Thicknesses, and Diameters Qualified.PJP and Fillet Welds Tubular T-, Y-, or K-Connections and Butt Joints.CJP Groove Welds for Tubular Connections.Type of Qualification Tests, Methods of Testing, and Acceptance Criteria for WPS Qualification.Part C – Welding Procedure Specification (WPS) Qualification Part B – Prequalification of Welding Procedure Specifications (WPSs) Identification and Parts of Tubular Connections.Manufacturers’ Stud Base Qualification Requirements.

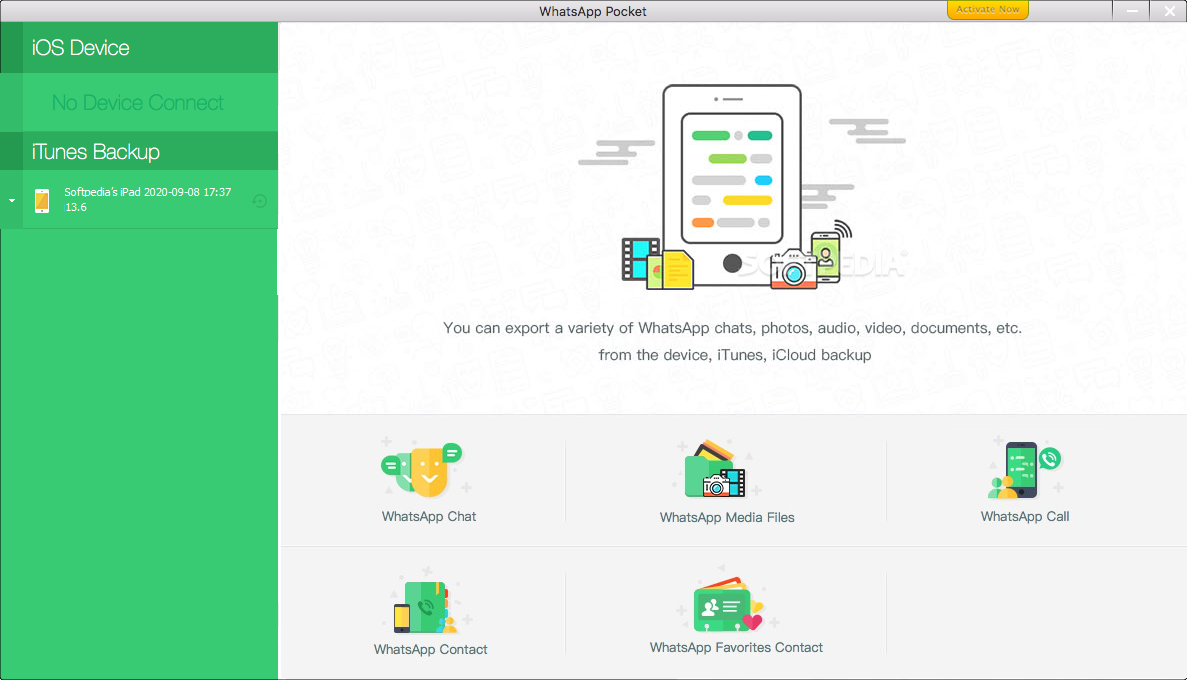

WHATSAPP POCKET 6.9.9.3 CRACK FULL VERIFICATION

Dimensional Tolerance of Welded Structural Members.Weld Access Holes, Beam Copes, and Connection Material.Heat Input Control for Quenched and Tempered Steels.Welding Consumables and Electrode Requirements.Combining FCAW-S with Other Welding Processes in a Single Joint.Part D – Requirements for CVN Toughness Testing Method of Testing and Acceptance Criteria for Tack Welder Qualification.Methods of Testing and Acceptance Criteria for Welder and Welding Operator Qualification.CJP Groove Welds for Nontubular Connections.Preparation of Performance Qualification Forms.Weld Types for Welder and Welding Operator Performance Qualification.Welding Processes Requiring Qualification.Methods of Testing and Acceptance Criteria for WPS Qualification.WPS Requirements for Production Welding Using Existing Non-Waveform or Waveform WPSs.Part B – Welding Procedure Specification (WPS) Qualification Common Requirements for WPS and Welding Personnel Performance Qualification.Preheat and Interpass Temperature Requirements.Part F – Preheat and Interpass Temperature Requirements Part E – Filler Metals and Shielding Gases Part C – Specific Requirements for Design of Nontubular Connections (Cyclically Loaded) Joint Configuration and Details – Plug and Slot Welds.Joint Configuration and Details – Fillet Welded Joints.Joint Configuration and Details – Groove Welds.Part B – Specific Requirements for Design of Nontubular Connections (Statically or Cyclically Loaded) Part A – Common Requirements for Design of Welded Connections (Non-tubular and Tubular Members) It provides provisions specific to the responsibilities of the inspectors, contractors, and engineers.

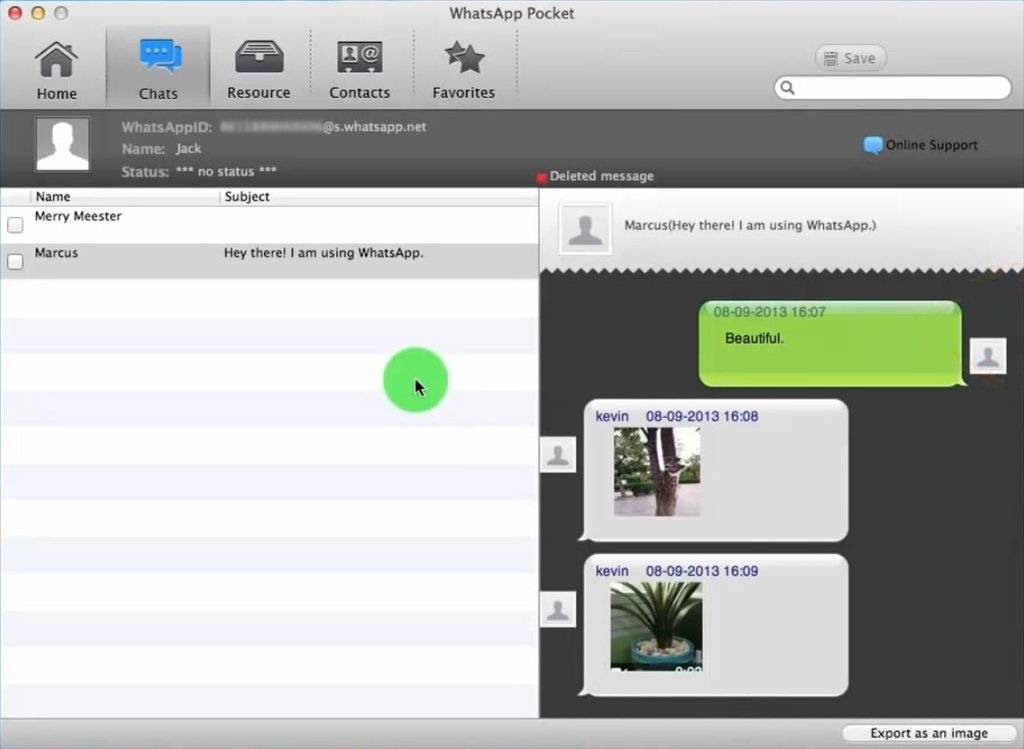

WHATSAPP POCKET 6.9.9.3 CRACK FULL CODE

In addition, the AWS D1.1:2020 code includes information pertinent to its stipulation in contract documents as well. It also explains numerous other considerations namely fatigue stress design parameters and prequalified welding procedure specifications. They include fillet welds, groove welds, plugs, and slot welds. Further, this Code reveals a comprehensive approach to outlining specific connections and welds. Further, as the quality increases and rework decreases.ĪWS D1.1 – 24th Edition contains the requirements for fabricating and erecting welded steel structures. The main purpose of the code is to assure quality and consequently, the quality of the products will increase. It contains much more than just details on the qualification process. The Code is specified as the quality standard in hundreds of contract documents every year. AWS D1.1/D1.1M Structural Welding Code – Steel is the most widely used welding code in the United States and the world.

0 kommentar(er)

0 kommentar(er)